Project details

Category: Containment

Status: Complete

Client:

United Kingdom Atomic Energy Authority (UKAEA)

For more information:

Aims and objectives

Aquila won the contract for the design, manufacture, assembly and function testing of four WDS Valve Boxes for the United Kingdom Atomic Energy Authority (UKAEA).

About the client

Wood provides performance-driven solutions throughout the asset life cycle, from concept to decommissioning across a broad range of industrial markets including the upstream, midstream and downstream oil & gas, power & process, environment and infrastructure, clean energy, mining, nuclear, and general industrial sectors.

Project Overview

Aquila won the contract for the design, manufacture, assembly and functional testing of four WDS Valve Boxes for the United Kingdom Atomic Energy Authority (UKAEA).

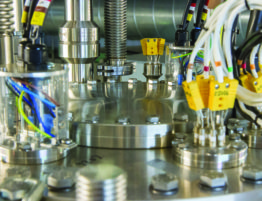

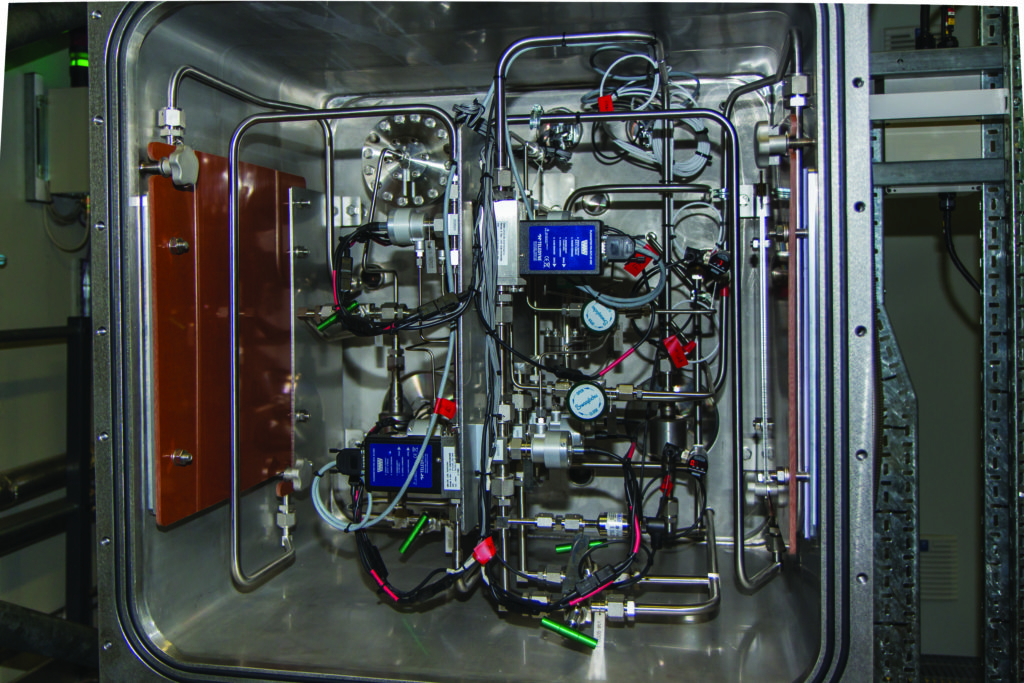

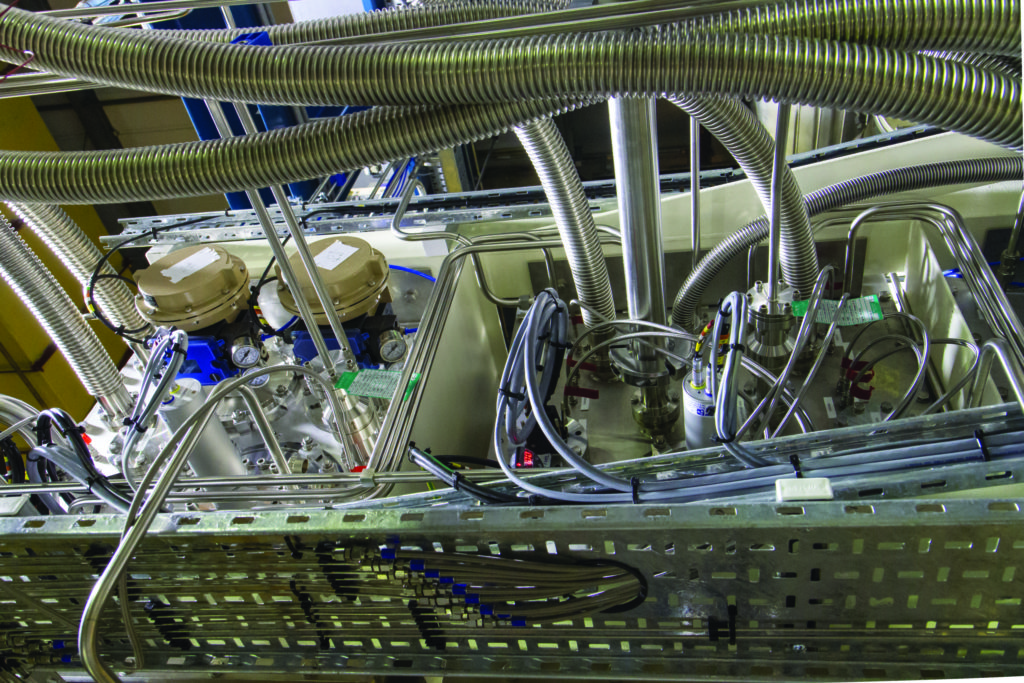

The valve boxes were designed as a flanged carcasses with control closure panels on each end, to aid manufacture and maintenance access, to which the primary pipework is mounted. Process control connections are located on the control closure panel, which the secondary pipework interfaces are located on the flanged carcass. Four mounting feet on the base of the flanged carcass support the complete assembly.

All primary process pipework and cabling was designed to be mounted onto a single closure panel – the control closure panel. A supplementary valve mounting pate, mounted to the control closure panel, increases the surface area available for component mounting, maximising utilisation of the box volume, minimising the box footprint and the process line length, while delivering a lighter box construction.

Summary

Aquila took the outline proposal detailed in the UKAEA specification and developed a solution that was simple, practical and cost effective. created a design that enabled the control closure panel manufacture to be ‘fast-tracked’ through production, enabling early initiation of the primary pipework fabrication and associated components. The design also aided fabrication and installation through improved access around the components, creating cost savings through simplification.