Aims and Objectives

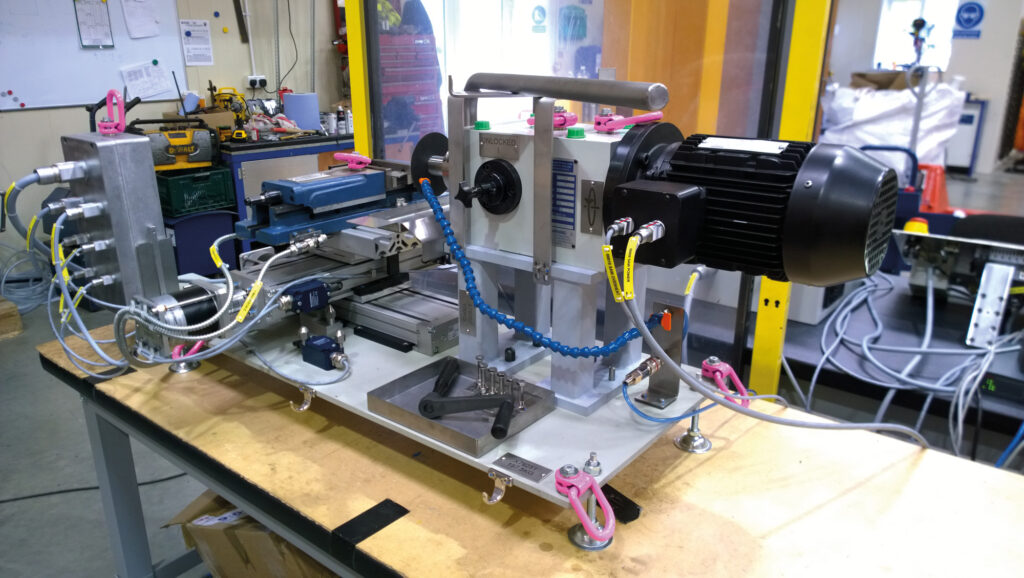

Aquila won the contract to design, manufacture, assemble and test a remotely operated diamond saw (RODS) for the National Nuclear Windscale Laboratory to support post irradiated examination (PIE) of samples within a shielded cave.

Project Overview

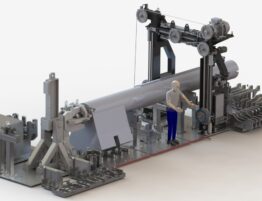

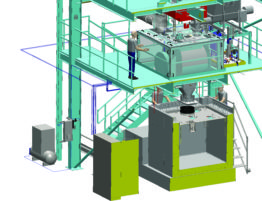

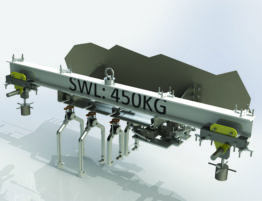

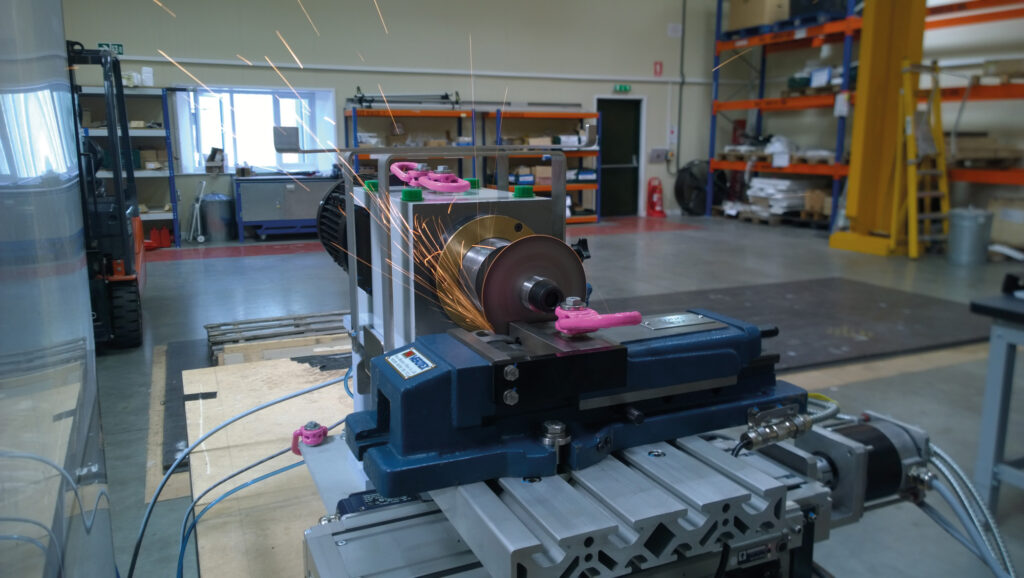

The RODS has been designed to support the process defined by NNL in support of its PIE operations, where samples are required to be analysed to determine mechanical and chemical properties using a variety of experimental techniques. The equipment is posted into the cave partially disassembled and is reassembled remotely with dedicated handling and guide features. The RODS enables a hardened irradiated metallic sample to be remotely prepared in size and shape prior to transfer to the designated analysis rigs.

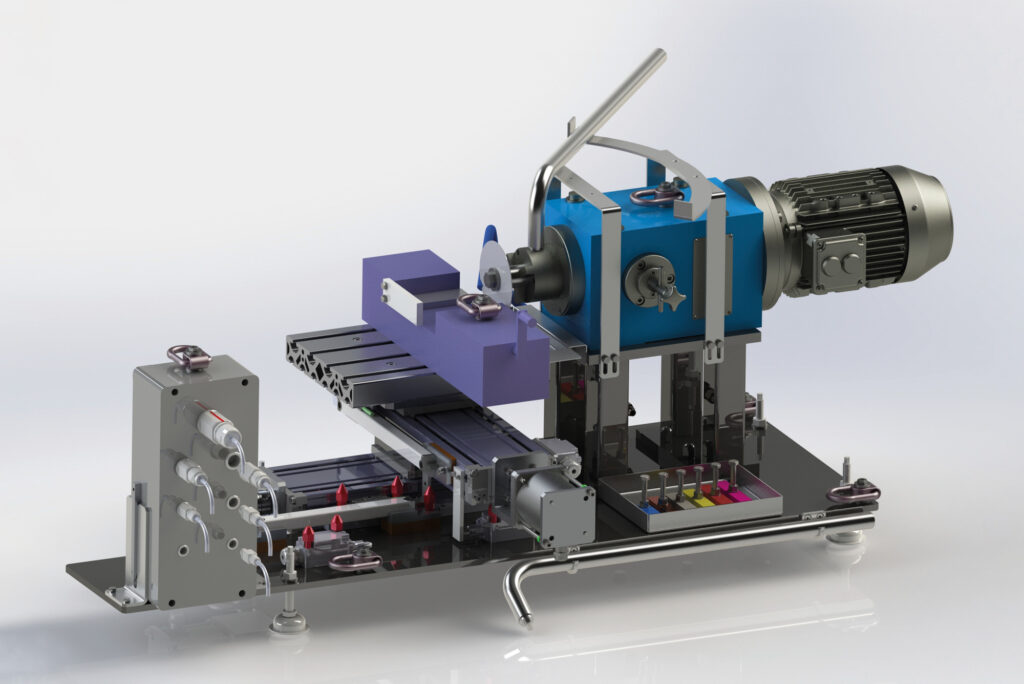

Versatile work holding and tooling arrangements, combined with a CNC positioning system utilised on other remotely operated equipment, allow NNL to develop and adapt the equipment to suit the uncertainties of the sample condition.

Aquila provided equipment with the functions specified, enabling NNL to be responsible for detailing full instructions with procedural controls, hold points, quality control, etc.

Summary

Aquila reviewed the detailed specification supplied by NNL and developed a Remotely Operated Diamond Saw which was simple, practical and cost effective. Careful selection and adaptation of Commercial off the Shelf (COTS) equipment kept much of the machine operation manual. This reduced the complexity of the machine and use of standard machine tools allows versatility for future operations. The RODS has been successfully designed and manufactured to enable irradiated samples to be remotely prepared in size and shape.